Product Description

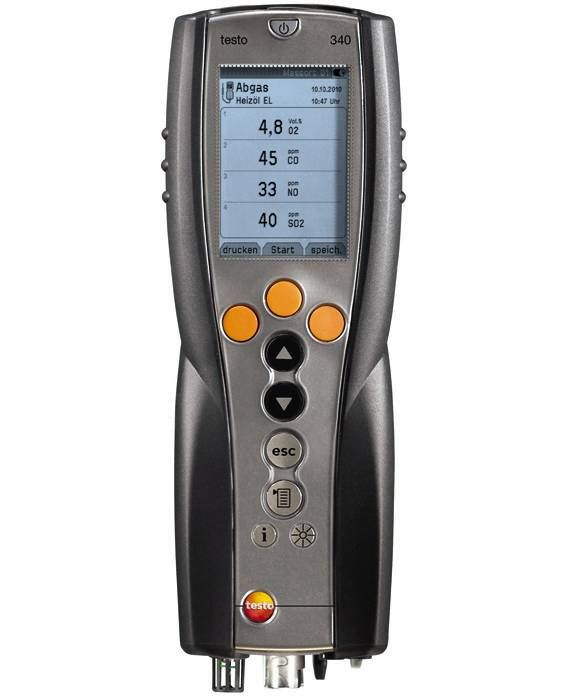

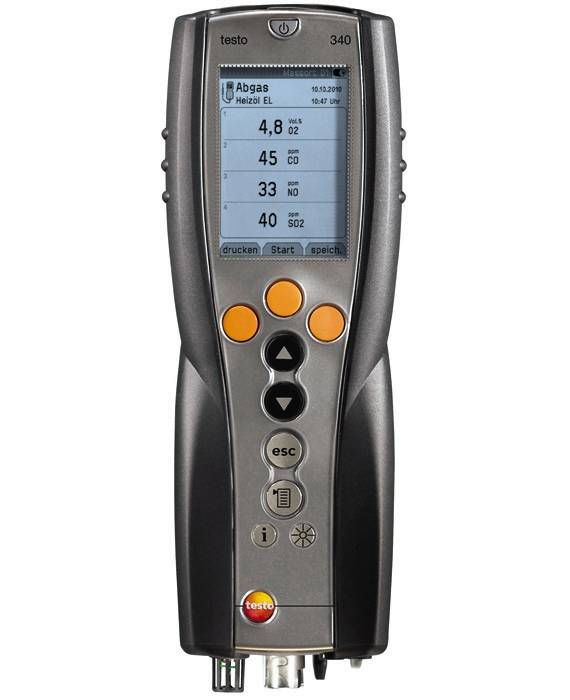

Precise technology: That’s what you can rely on when you’re working out in the field. But precise technology is nothing if it is not versatile, easy to use and adaptable for use in the field. The testo 340 flue gas analyzer meets all these expectations and much more.

Industrial emission measurement with testo 340 flue gas analyzer

Which sensors do you need in the course of your daily work and which measurements do you normally need to carry out? The testo 340 flue gas analyzer comes standard-fitted with an O2 sensor and four more sensors (CO, COlow, NO, NOlow, NO2 or SO2 ) for you to choose from, allowing you to customize your flue gas analyzer to suit your individual demands. The analyzer’s compact design and the reliable technology ensure increased mobility, making it ideal for use in on-site service operations and for installing or carrying out checks on firing plants or energy production systems. To find out more about the different application possibilities and to see which industrial applications your testo 340 flue gas analyzer is suitable for, just click on the “Applications” tab.

High gas concentrations? No problem with the flue gas analyzer testo 340!

The flue gas analyzer has an extended measuring range which allows you to carry out measurements even when gas concentrations are very high (i.e. during industrial flue gas analysis). The extended measuring range (thinning) is activated automatically when high gas concentrations suddenly occur. The demands on the sensor are no different to than when the flue gas analyzer is used in low gas concentrations.

Delivery Scope

testo 340 flue gas analyzer, calibration certificate, shoulder strap, O2 sensor and integrated flow and pressure difference measurements.

Please note that your testo 340 must be fitted with a second gas sensor for it to work. Up to three additional sensors can be fitted.

| Differential Pressure - Piezoresistive |

| Measuring range |

-200 to 200 hPa

|

| Accuracy |

±0.5 hPa (-49.9 to 49.9 hPa)

±1.5 % of mv (Remaining Range)

|

| Resolution |

0.1 hPa

|

| Absolute Pressure |

| Measuring range |

+600 to +1150 hPa

|

| Accuracy |

±10 hPa

|

| Resolution |

1 hPa

|

| Flue gas O? |

| Measuring range |

0 to 25 Vol.%

|

| Accuracy |

±0.2 Vol.%

|

| Resolution |

0.01 Vol.%

|

| Reaction time t?? |

< 20 s

|

| Flue gas CO (with H?-compensation) |

| Measuring range |

0 to 10000 ppm

|

| Accuracy |

±10 ppm or ±10 % of mv (0 to 200 ppm)

±20 ppm or ±5 % of mv (201 to 2000 ppm)

±10 % of mv (2001 to 10000 ppm)

|

| Resolution |

1 ppm

|

| Reaction time t?? |

< 40 s

|

| Flue gas COlow |

| Measuring range |

0 to 500 ppm

|

| Accuracy |

±2 ppm (0 to 39.9 ppm)

±5 % of mv (Remaining Range) data corresponds to 20°C ambient temperature. Additional temperature coefficient 0.25% of reading/K.

|

| Resolution |

0.1 ppm

|

| Reaction time t?? |

< 40 s

|

| Flue gas NO |

| Measuring range |

0 to 4000 ppm

|

| Accuracy |

±5 ppm (0 to 99 ppm)

±5 % of mv (100 to 1999 ppm)

±10 % of mv (2000 to 4000 ppm)

|

| Resolution |

1 ppm

|

| Reaction time t?? |

< 30 s

|

| Flue gas Nolow |

| Measuring range |

0 to 300 ppm

|

| Accuracy |

±2 ppm (0 to 39.9 ppm)

±5 % of mv (Remaining Range)

|

| Resolution |

0.1 ppm

|

| Reaction time t?? |

< 30 s

|

| Flue gas NO? |

| Measuring range |

0 to 500 ppm

|

| Accuracy |

±10 ppm (0 to 199 ppm)

±5 % of mv (Remaining Range)

|

| Resolution |

0.1 ppm

|

| Reaction time t?? |

< 40 s

|

To avoid absorption, a maximum measurement duration of 2 hours should not be exceeded.

±10 % of mv (Remaining Range)

| Flue gas SO? |

| Measuring range |

0 to 5000 ppm

|

| Accuracy |

| Resolution |

1 ppm

|

|

±10 ppm (0 to 99 ppm)

| Reaction time t?? |

< 40 s

|

To avoid absorption, a maximum measurement duration of 2 hours should not be exceeded.

| Flue gas Draught |

| Measuring range |

-40 to +40 hPa

|

| Accuracy |

±0.03 hPa (-2.99 to +2.99 hPa)

±1.5 % of mv (Remaining Range)

|

| Resolution |

0.01 hPa

|

| Temperature |

| Measuring range |

-40 to +1200 °C

|

| Accuracy |

±0.5 °C (0 to +99 °C)

±0.5 % of mv (Remaining Range)

|

| Resolution |

0.1 °C

|

| Flue gas degree of effectivity, Eta (calculated) |

| Measuring range |

0 to 120 %

|

| Resolution |

0.1 %

|

| Flue gas loss (calculated) |

| Measuring range |

0 to 99.9 %

|

| Resolution |

0.1 %

|

| Flue gas dewpoint (calculated) |

| Measuring range |

0 to 99.9 °Ctd

|

| Resolution |

0.1 °Ctd

|

| Flue gas CO? calculation (calculated from O?) |

| Measuring range |

0 to CO? max

|

| Accuracy |

±0.2 Vol.%

|

| Resolution |

0.1 Vol.%

|

| Reaction time t?? |

< 40 s

|

| General technical data |

| Dimensions |

283 x 103 x 65 mm

|

| Operating temperature |

-5 to +50 °C

|

| Housing |

TPE PC

|

| Protection class |

IP40

|

| Warranty |

Measuring instrument 2 years (excepting wearing parts e.g. gas sensors, etc.); rechargeable battery: 12 months; CO sensor: 12 months; Sensor NOlow: 12 months; Sensor NO2: 12 months; Sensor SO?: 12 months; Sensor O?: 18 months; NO sensor 12 months; COlow sensor 12 months

|

| Display size |

160 x 240 pixels

|

| Display function |

Graphic display

|

| Power supply |

Battery block 3.7 V / 2.4 Ah, Mains unit 6.3 V / 2 A

|

| User defined fuels |

10 user-defined fuels incl. test gas as fuel

|

| Max. neg. press./flue gas |

-200 mbar

|

| Max. pos. press./flue gas |

50 mbar

|

| Hose length |

max. 7.8 m (corresponds to two probe hose extensions)

|

| Pump flow |

0.6 l/min (regulated)

|

| Maximum |

100 folders

|

| Storage per folder |

Max. 10 sites

|

| Storage per site |

Max. 200 logs

|

| Miscellaneous |

The max. number of logs is determined by the number of folders or sites

|

| Storage temperature |

-20 to +50 °C

|

| Weight |

960 g

|